The art and science of orthosis manufacturing has improved progressively in the last decades within small cycles. However, correct handling of the most demanding cases such as Scoliosis and Kyphosis is either overpriced, substandard or even non-existent depending on your location.

In Osteoid, we provide our partners components of an entire turn-key manufacturing system, know-how, and training to enable on site manufacturing of gold standard spinal braces for a fraction of the time and cost.

Osteoid's turn-key manufacturing systems include 3D brace libraries, 3D design software with artificial intelligence decision support systems and 3D printing solutions to provide the most reliable and efficient trunk brace manufacturing.

Clinical Workflow

Diagnosis

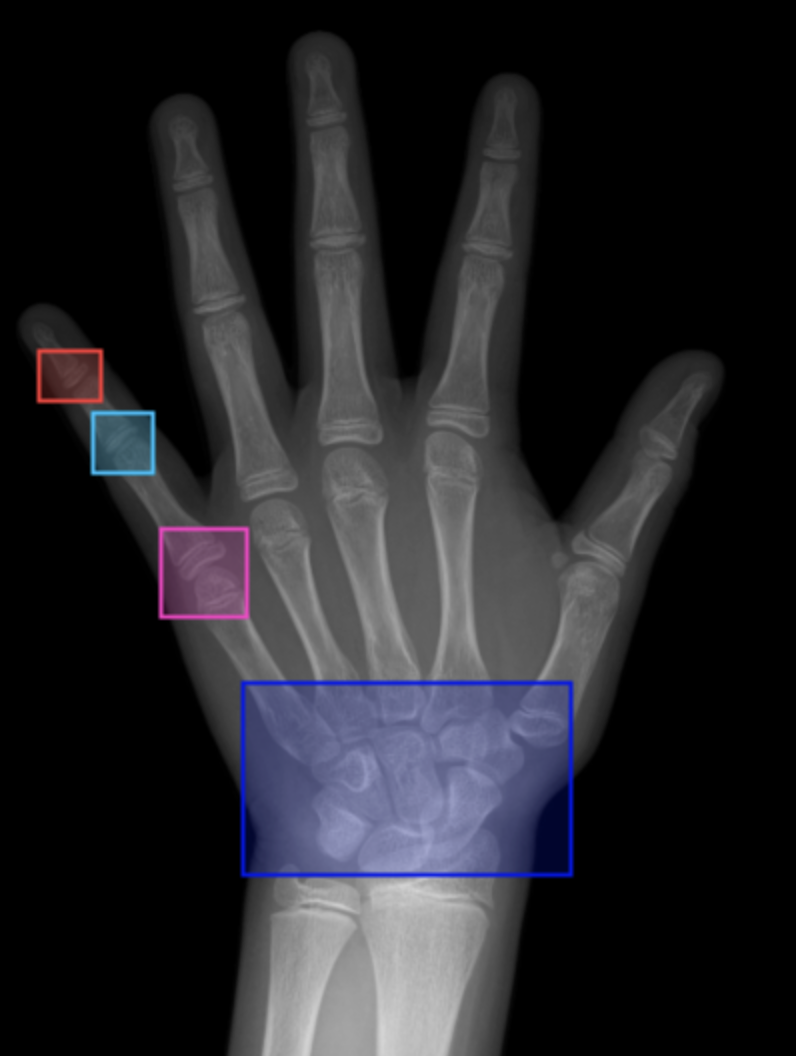

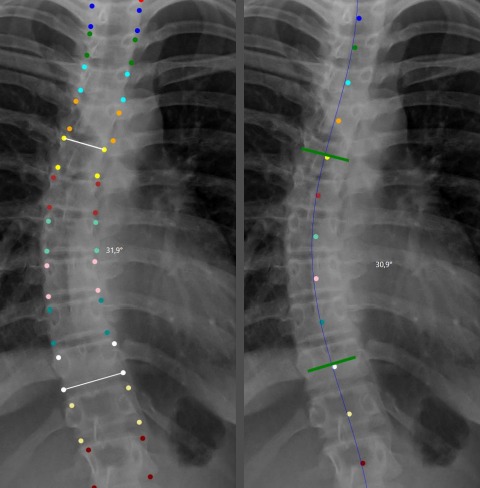

The diagnosis of scoliosis and Kyphosis should be made by an Orthopedic or physical therapy and rehabilitation doctor, who is an expert in the field of conservative treatment. This is done by the doctor evaluating the x-ray of the spine looking at the clinical picture of the patient and using a Scoliometer to measure the rotation of the trunk. If the bone development (risser scale), Cobb Angle and rotation of the spine is suitable for conservative treatment the patient is then referred it to a Orthopedic Workshop specializing in Scoliosis, by the doctor. The orthotist who is an expert in his field, then classifies the curvature in accordance with the Cheneau classification and continues with the selection of the appropriate base model from our Osteoid software.

3D Scanning

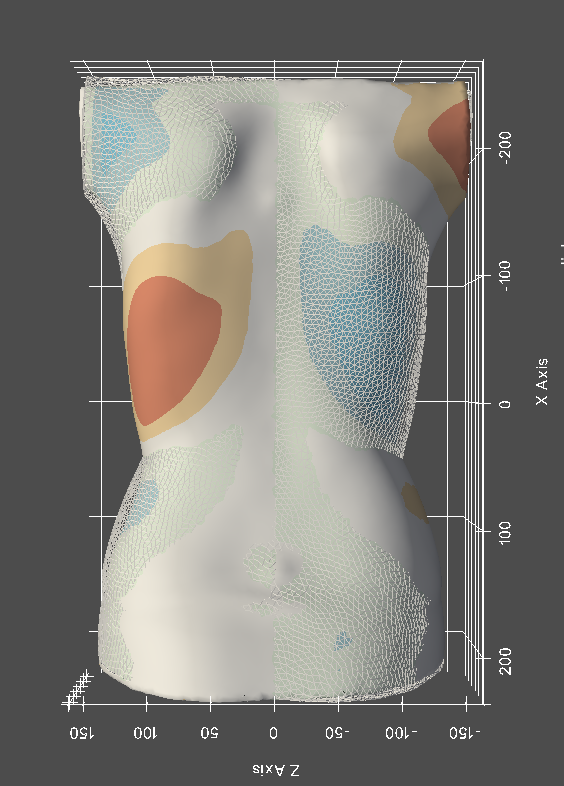

With the iPad, 3D scanning apparatus and 3D scanning software developed by our company, the patient's body is transferred to the 3D software environment in the most practical and fastest way possible, without touching the patient's body. Photographs of the patient are taken at various angles and positions to receive an optimal clinical picture of the patients rotation.

C.A.D.

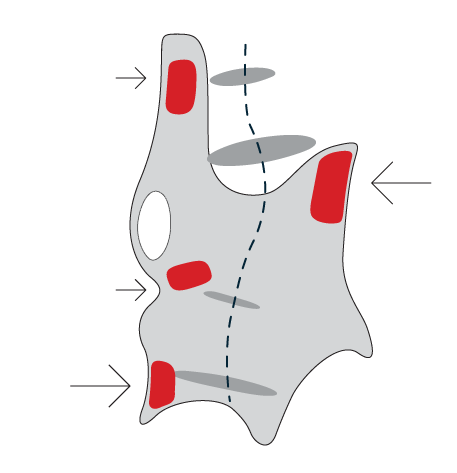

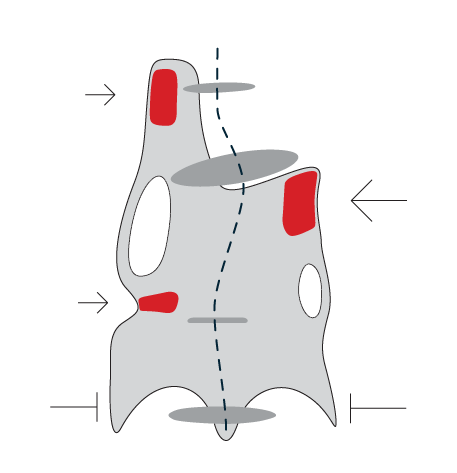

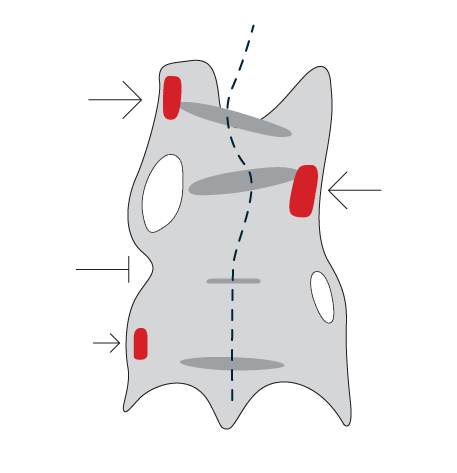

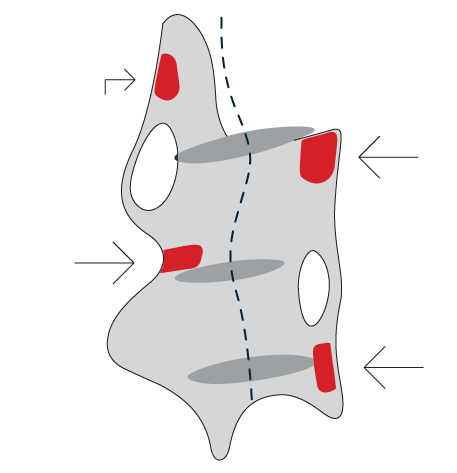

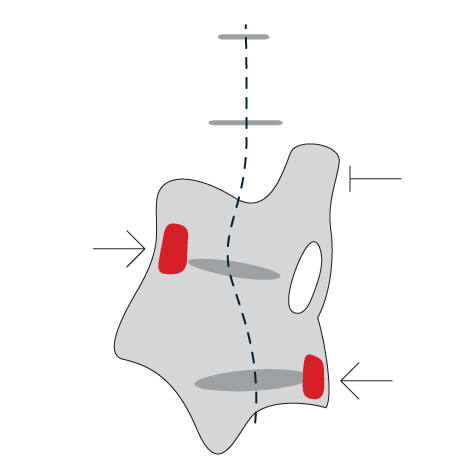

The CPO enters the patients body scan and measuremts into the Osteoid 3D software during which a 3d base model is chosen in accordance with the patients data. The 3d brace model is designed to be the most suitable for each unique patient, with the CPO being able to perfect the standard model by adjusting pressure points, gravity line, rotation, and pelvic tilt.

3D Manufacturing

After the design of the personalized brace is completed the data will then be transferred to the Osteoid 3D printer that was specially developed for fast and easy manufacturing. This process is completed in an average of 7-10 hours with an extruder designed and developed by Osteoid in order to make the brace suitable for the patient to wear. When the 3D printer is finished printing the personalized brace, the CPO removes and prepares the brace for fitting on the patient.

Treatment

During the fitting the CPO (trained by one of Osteoid experts) adapts the brace to the patients body for a perfect fit all the while, taking into account the biomechanics of the brace and patients spinal deformity by using pads to increase pressure or give a more wider flatter surface pressure. After a period of about 2 hours the CPO cuts ad smooths the Thermoplastic material (Osteoid PE) for a better and more comfortable fit for each individual patient. After a period of approximately 10 weeks the doctor will prescribe an in-brace x-ray, which will show the doctor and CPO where and to which affect the 3d pressure is having on the spinal deformity. With a before and after picture to see any change on the patients clinical picture the doctors and CPO will then take this information together with the in brace x-ray and make any necessary adjustments to the brace if needed.

Brace Library

Due to the decades of experience invested into standardized brace models, we make sure that each specific curve pattern is treated with the same biomechanical principles.

The basic library is coherent with the Schroth method and consists of 5 Chêneau type scoliosis braces, 2 Kyphosis braces, and one symmetrical post op-brace.

We also enable our partners to parameterize their own designs and ideas by developing custom software solutions.

Artifical Intelligence

Yapay zeka modellerimiz, kullanıcının karar verme yeteneklerini geliştirmek ve desteklemek amacıyla geliştirilmiştir. Bu, cerrahi olmayan tedavi sonuçlarının sistematik olarak iyileştirilmesiyle sonuçlanır ve profesyoneller için bir tedavi planı formüle etme süresini hızlandırır.

Brace Classification AI

This state of the art model is trained with patient trunk 3D scans which are processed with 3D geometry algorithms and deep learning to make sure that correct brace models are selected for each individual patient.

Risser AI

The Risser scale is a grading system used to assess skeletal maturity. In scoliosis, the Risser scale is used to determine the potential for further progression of the spinal curvature. The Risser scale is often used in conjunction with other measurements and assessments to determine the appropriate treatment plan for scoliosis patients. Risser Ai is a deep neural network trained for assessing the skeletal maturity of the patient.

Cobb Measurement AI

The Cobb angle is a crucial measurement used in the diagnosis and treatment of scoliosis, providing valuable information to doctors and specialists in determining the severity of the curvature and making treatment decisions; however intraobserver variability may cause misdiagnosis and misevaluation of the effectiveness of the treatment. Cobb Ai is a deep neural network trained for detecting vertebra corners or centroids with ease and precision.

Personalization

Digitised brace libraries combined with parametric software is the backbone of Osteoid solutions. Easily customize the standardized brace models with the 3D modeling parametric interface.

Osteoid software gives you the opportunity to determine patient-specific parameters such as, de-rotation and amount of compression while showing the effects on the patient during a virtual fitting in a digital environment.

3D Printer

Osteoid'in 3D baskı çözümleri, oyma, termoformlama ve atık yönetimi gibi geleneksel imalat süreçlerine bağlı olan iş saatlerini ve çoklu işlemleri en aza indirmek için tasarlanmıştır. Değerli varlıkların başka yerlerde kullanılabilmesi için tasarruf sağlar. Osteoid endüstriyel 3D yazıcımız, özel bir pelet ekstrüzyon ünitesi ve geleneksel yönlendirme makineleri ile kolayca kesilebilen, öğütülebilen ve cilalanabilen özel bir termoplastik malzeme ile donatılmıştır.

Osteoid'in 3D baskı çözümleri, oyma, termoformlama ve atık yönetimi gibi geleneksel imalat süreçlerine bağlı olan iş saatlerini ve çoklu işlemleri en aza indirmek için tasarlanmıştır. Değerli varlıkların başka yerlerde kullanılabilmesi için tasarruf sağlar. Osteoid endüstriyel 3D yazıcımız, özel bir pelet ekstrüzyon ünitesi ve geleneksel yönlendirme makineleri ile kolayca kesilebilen, öğütülebilen ve cilalanabilen özel bir termoplastik malzeme ile donatılmıştır.

| Specifications | |

|---|---|

| Method | Pellet Extrusion |

| Slicer | Osteoid |

| Material | Osteoid PP |

| Brace Print Time | 6 to 9 Hours |

| Printer Volume | 120 x 90 x 170 cm |

| Print Volume | 55 x 55 x 75 cm |

| Weight | 195 kg |

| Temperature Control | 3 area |

| Nozzle Diameter | 3.0 / 3.5 / 4.0 mm |

| Extruder Temperature | 0 - 280 °C |

Contact

Osteoid Health Technologies

Adress: Reşitpaşa District, Katar Avenue

Teknokent ARI 1

Sarıyer / İstanbul

E-mail : [email protected]