Diagnosis

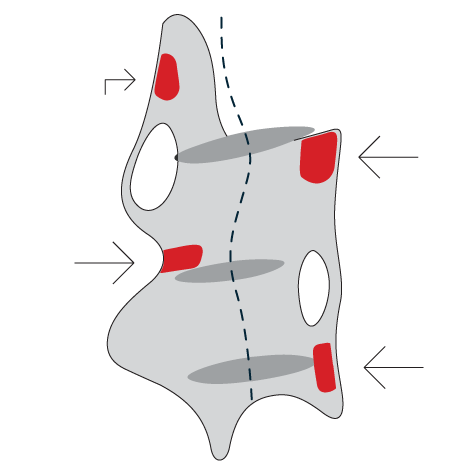

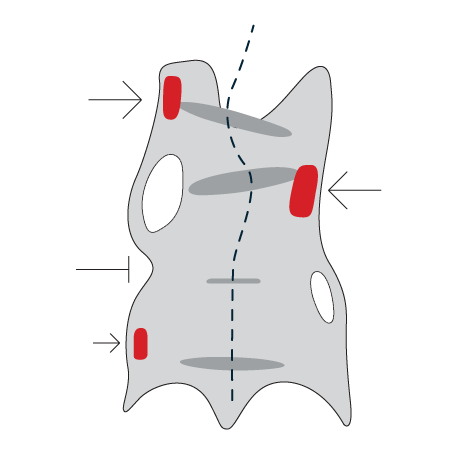

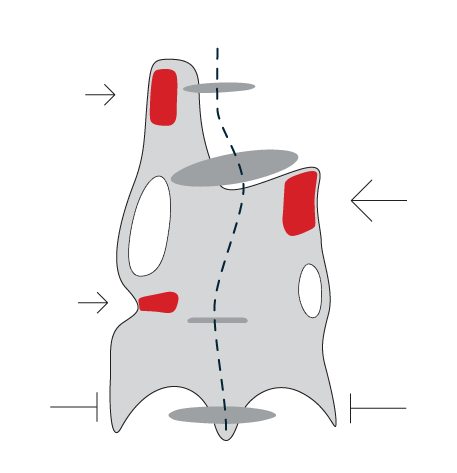

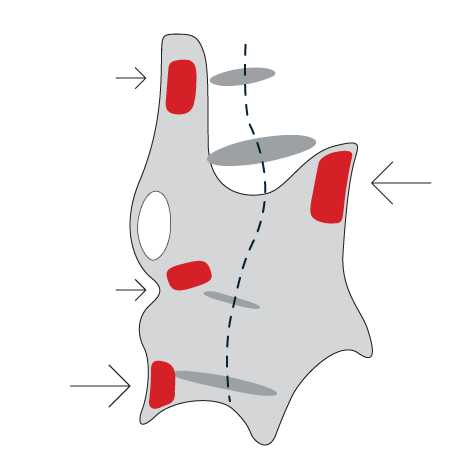

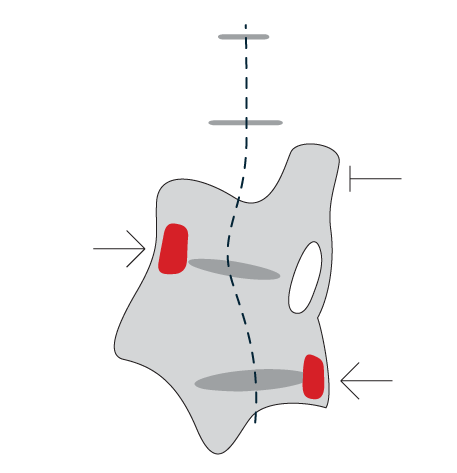

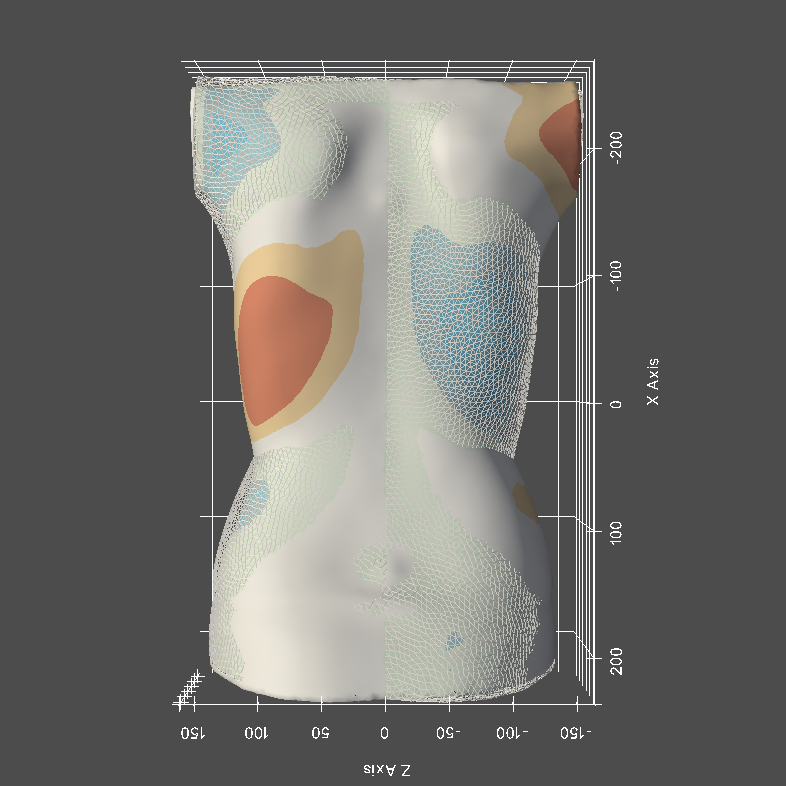

Diagnosis is performed by a specialist (Orthopedics or PM&R) using X-rays and a Scoliometer. If the patient's metrics (Risser scale, Cobb Angle, rotation) suit conservative treatment, they are referred to a specialized Orthopedic Workshop. The orthotist then uses the Cheneau classification to select a base model via our Osteoid software.